Woodworker: n, someone who makes things out of wood.

I’ve worn many a hat in my day; certified FEMA participant, negligent bystander, person of interest, employee of the month, passive aggressive enabler, delusional prophet of impending doom, licensed insurance salesman, assistant number 6031, that asshole on the fifth floor, dog bite victim, and fat little Dixie Chick. None has fit me as well as the “woodworker” hat, although fat little Dixie Chick is a close second. OK, I was never the fat little Dixie Chick. I suppose “liar” might be more technically accurate, but my, what an ugly little word. Let’s agree on “grandiose” and move on to my woody new hat.

What impetuous, you might wonder, has led to my recent haberdasherous hijinks? They say a picture is worth a thousand words, even made-up words (which my spell check insists I create with alarming frequency...perhaps I should add “linguistic innovator” to my list of hats), so I offer the following visual explanations:

Some people claim that kitchen cabinets are for food, dishes, or other kitchen related items, not for an increasingly unmanageable Simpsons collection. This is why I point out that we’ve bought a separate kitchen hutch for those kinds of things.

How the hutch, too, became filled with Simpsons items is inexplicable. Well, I guess “inexplicable” isn’t really the most technically accurate word. There I go being grandiose again. But if we’re going to play the blame game, let’s at least play fair. Our house is only so big and suffers from a severe lack of designated storage space...no doubt because I’ve also filled those other spaces with my collection. What’s pictured here represents about half of the total. A fair amount of the blame belongs to Shawn, who has duplicates of roughly half the items in my collection, all of which also require storage. And then there are the dogs, whose indiscrimination between vintage mint-in-box collectibles and Snausages makes any open display a mere smorgasbord. And finally, I blame Arizona, the dustiest state in the union. It’s uncanny; with all the windows shut to keep the air conditioning in and the 115 degree ozone-laden air out, a thin layer of dust will still accumulate within an hour after any surface is cleaned. Dust is not a collector’s friend, especially a lazy collector.

Nor does the collector find joy in all his treasures being hidden away in hutches or closets. Not only is my collection a source of deep personal pride, it also represents about a quarter of my income since 1997. This is not a light I want hidden under a bushel. We searched the far and wide Phoenix area for an appropriately large and reasonably priced display case of some kind for the collection, but came away empty handed. Little did we know it at the time, but that journey’s end was the beginning of another, for there was but one practical solution to our problem. We must design and build our own custom display case. Such an undertaking would demand skills we hadn’t yet developed, know-how we didn’t yet know, and machines with high pitched motors and sharp, sinister blades we hadn’t yet purchased. Rome was not built in a day, and this display case won’t be, either. It’s an apt analogy because the two are likely to end up roughly the same size. OK, that’s not technically true, either. Let’s just say that the display case will be, in its own way, Romanesquely grandiose.

The first step was painfully obvious. We’d need a moderately priced table saw to get the project up and running. I already had a hammer, a ruler, and a red toolbox. I was ready to hammer in the morning, I was ready to hammer in the evening...all over this land, your land, my land, from California to the New York Island, this log, it used to be a tree. All I needed was a reliable, accurate way to cut all kinds of wood.

And so it was that Shawn and I found ourselves at a Home Depot having the following discussion:

“Say, Shawn, isn’t that a Ridgid TS24000LS Portable Job Site Saw on a patented Work-N-Haul-It table saw cart over there?”

“Sure looks like one to me. See the heavy-duty 15 amp motor with the belt driven 5/8 inch arbor? That sucker can do 4,000 RPM’s.”

“No shit? What’s the maximum ripping capacity?”

“25 inches right side of the blade, 12 inches left.”

“That is one sweet looking carbide tipped blade. Bet that baby has a cut depth of over 3 inches.”

“3 and one eighth, to be exact.”

“Whoa, did you see this Retract-A-Rip fence and rail system? Those are dual cams on that fence, baby. Rick solid.”

“And that lightweight but durable cast aluminum table top is smooth.”

“Extruded aluminum is shit, bro. You gotta have cast aluminum.”

“Yep, I reckon it’ll do. Let’s us grab our crotches, spit carelessly in random directions, and throw this here saw in the back of the pick-up.”

Maybe it’s the Sodium Barbitol talking, but I must again fess up to being grandiose. The real conversation went more like this:

“Hey, Shawn, what do you think of this saw?

It’s orange.”

“I like orange.”

“Me, too!”

“Orange is, like, my favorite color.”

“Get out! Me, too!”

“So should we get it?”

“Well. Do we need one that big?”

“Sure. I mean, why not?”

“What’s this thing do?”

“Hmmmm. I’m not sure. This here is the blade, though. That cuts the wood.”

“I see. Isn’t this wheel in front supposed to turn?”

“I think so. I don’t really know.”

“Oh.”

“Maybe the display model is broken.”

“Oh.”

“So what do you think?”

“What’s ripping?”

“Ripping? Where does it say that?”

“It says, ‘Maximum ripping capacity 25 inches.’ Is ripping a good thing?”

“I wouldn’t think so, but maybe it is. Think that’s enough ripping? Do we need more ripping or less?”

“Do you know anything about table saws?”

“Well, I know we need one.”

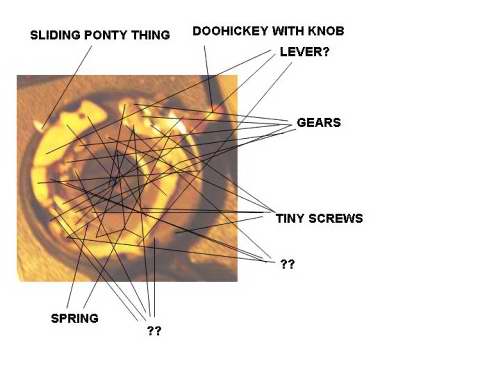

Every weekend for a month, I dragged Shawn to Home Depot, Sears, Lowe’s, and then back to Home Depot, and then back to Sears, and then back to Home Depot, then to Sears again, and then to Lowe’s... Along the way I amassed a wealth of table saw knowledge. Ripping (cutting wood across the grain) is indeed a good thing, and more is better. I know what a riving blade, a kerf, and a throat plate are. I know what the difference between a T-Slot miter gage and a sliding miter table. I know what kickback is and why an anti-kickback prawl is important. And I know why arbor size matters. This knowledge, though, came at a terrible personal cost....to Shawn.

To this day the life drains from his face the second we step into a home improvement warehouse, and both “Tool World” and the “Tool Corral” have been ruined for him forever. I suppose I’m to blame. After all, it was I who would repeatedly stand him in front of a saw and present him with the query, “What do you think?” “It’s nice,” he’d say. “Nice? It’s a tale saw,” I’d say. “It’s not supposed to be nice. It’s supposed to be a terrifying display of limitless power.” “Oh,” he’d say. “It looks fine.” Toward the end, all he’d say was, “It looks just like every other saw,” and then claim he had a headache and needed to go home.

Choosing a saw turned out to be nowhere near as complex as I’d made it, though. Every pro of every saw had an equal and opposite con, and eventually you’ve got to just pick something and live with it. Picking something became much easier when a budget was introduced, and the final decision was a breeze. We got the saw that was in our price range and in stock, which, ironically, was the Ridgid TS24000LS Portable Job Site Table Saw on the patented Work-N-Haul-It cart.

I will also admit, however, that getting a full sized table hasn’t helpful in terms of making more space, even with the fold down patented Work-N-Haul-It cart. But that’s merely an egg broken for the omelet. I now spend my Saturdays out in the blistering heat on the back porch cutting wood, often with a purpose. The fun thing about sweating profusely and running a table saw is that all the sawdust sticks to you. That’s when you have to make sure Shawn isn’t looking and jump into the pool for a quick rinse off. Just remember to suggest that perhaps the filter isn’t working properly when he wonders why the pool gets dirty so fast. Wearing safety goggles in that kind of heat will lead to the amazing discovery of just how much that small covered part of your face can sweat. I have to keep stopping every now and again to empty the pools of sweat that collect in the goggles when they reach eye level. It’s quite disgusting, but it’s all of part of the creative process.

And what, you may wonder, have I created thus far? Well, I’m glad you asked. Early on in my quest for table saw knowledge, I came across and became obsessed with finger (or box) joints. It was my idea that the entire cabinet could be assembled using these attractive and sturdy joints.

I constructed a jig to make the joints, and it came out splendidly. I’m not being grandiose, it really did. The only problem is that the two pieces never quite fit together, and I wind up pounding then with a hammer screaming “Fit, damn you, fit!” until something splits and I have a enraged meltdown. We could have bought a second Ridgid TS24000LS for the amount of money I’ve wasted on wood I’ve ruined, but I refuse to admit defeat, even if Shawn has to get a second job to pay for materials. I’m just that committed. Besides, a woodworker is someone who makes “things” out of wood. I’ve made some things. Mostly they look like splintered pieces of hammer-beaten wood half glued together, but they are things. Ergo, I am a woodworker.

You will see pictures of completed Simpsons display case on here before long. Oh yes, make no mistake about that, you will see it. And it will be grandiose.

I’ve been having a recurring dream where I’m teamed with Charo on a new reality TV series called “Don’t Drop the Taco!” At first I’m annoyed because a forty year old bag-boy from Cleveland gets paired with Hall of Famer Jim Palmer, clearly the most athletic of the bunch, while I’m paired with a has-been flamenco guitar player and geriatric booty shaker. Yeah, that’s fair. But later we’re all amazed to discover that Jim Palmer absolutely no good on water skis and a florist from Sacramento and Patti LaBelle prove to be stiffer competition in the Wacky Water Round. Although I’m relieved that our taco is soggy but undropped, I can’t help but feel that the only reason Charo is here is to plug her forthcoming album with the Salsoul Orchestra, Cuchi-Cuchi. “I haven’t been this exhilarated since I was a young girl growing up in Murcia, Spain,” Charo pants at the Wacky Water Round finish line, shaking the water from her sequined bathing suit, “the beautiful sounds of guitars flows there with the winds all the time. It’s the same sounds that flow in my new album, Cuchi-Cuchi, available in stores next month!” The show’s host, Tony Danza, nods enthusiastically while staring at the 65 year old Charo’s cleavage, which is considerably younger than the rest of her and promises to be on prominent display during the next round at The Pogo Stick Pagoda.

I’ve been having a recurring dream where I’m teamed with Charo on a new reality TV series called “Don’t Drop the Taco!” At first I’m annoyed because a forty year old bag-boy from Cleveland gets paired with Hall of Famer Jim Palmer, clearly the most athletic of the bunch, while I’m paired with a has-been flamenco guitar player and geriatric booty shaker. Yeah, that’s fair. But later we’re all amazed to discover that Jim Palmer absolutely no good on water skis and a florist from Sacramento and Patti LaBelle prove to be stiffer competition in the Wacky Water Round. Although I’m relieved that our taco is soggy but undropped, I can’t help but feel that the only reason Charo is here is to plug her forthcoming album with the Salsoul Orchestra, Cuchi-Cuchi. “I haven’t been this exhilarated since I was a young girl growing up in Murcia, Spain,” Charo pants at the Wacky Water Round finish line, shaking the water from her sequined bathing suit, “the beautiful sounds of guitars flows there with the winds all the time. It’s the same sounds that flow in my new album, Cuchi-Cuchi, available in stores next month!” The show’s host, Tony Danza, nods enthusiastically while staring at the 65 year old Charo’s cleavage, which is considerably younger than the rest of her and promises to be on prominent display during the next round at The Pogo Stick Pagoda.

When I tire of not being able to understand what anyone is saying, I turn to the Christian stations. While they do speak English, I still can't understand what most of them are saying. Or, more precisely, I can't understand why anyone would want to listen to what's being said. Did you know God doesn't want us to eat fatty foods high in carbohydrates? Did you know that Bible is not only the word of God, it's a cookbook? It's true. The televangelist I heard it from lost three inches from his waistline following a diet outlined by God. I also enjoy the frequent appearances of "celebrities" like Mr. T, Tracey Gold, and Kirk Cameron, all of whom claim to have been led to the brink of damnation by sinful Hollywood...as if any of them would know anything about Hollywood.

When I tire of not being able to understand what anyone is saying, I turn to the Christian stations. While they do speak English, I still can't understand what most of them are saying. Or, more precisely, I can't understand why anyone would want to listen to what's being said. Did you know God doesn't want us to eat fatty foods high in carbohydrates? Did you know that Bible is not only the word of God, it's a cookbook? It's true. The televangelist I heard it from lost three inches from his waistline following a diet outlined by God. I also enjoy the frequent appearances of "celebrities" like Mr. T, Tracey Gold, and Kirk Cameron, all of whom claim to have been led to the brink of damnation by sinful Hollywood...as if any of them would know anything about Hollywood.  And then there's Jan Crouch, darling of the Trinity Broadcasting network. Aside from hosting Christian liposuction seminars and speaking in tongues, she travels the globe terrifying sick and underprivileged children in the name of charity and ratings.

And then there's Jan Crouch, darling of the Trinity Broadcasting network. Aside from hosting Christian liposuction seminars and speaking in tongues, she travels the globe terrifying sick and underprivileged children in the name of charity and ratings.  The New Year is coming at me faster than a sack of potatoes dropped from considerable height...say, from the top of the Stratosphere Casino, or off the Golden Gate Bridge. Actually, the chances of me being under the Golden Gate Bridge when a person or persons unknown decided to fling a sack of potatoes off of it are pretty slim, especially since I'd have to be in a boat. I am seldom found boating nowadays, and I've never been to San Francisco. (Did you know that Arizona has more boats per capita than any other state in the union? It's true!) I've been to the Stratosphere Casino in Las Vegas, but the only thing that fell on my head there was rain. Actually, the whole "being struck from above by a sack of potatoes dropped from considerable height" scenario isn't very likely, which makes it a terrible metaphor for inevitability. I guess I'm just not on top of my game today, which isn't surprising, considering my mood.

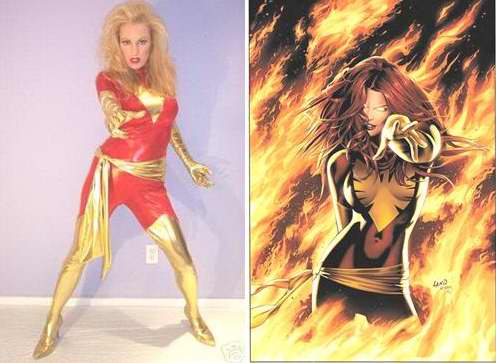

The New Year is coming at me faster than a sack of potatoes dropped from considerable height...say, from the top of the Stratosphere Casino, or off the Golden Gate Bridge. Actually, the chances of me being under the Golden Gate Bridge when a person or persons unknown decided to fling a sack of potatoes off of it are pretty slim, especially since I'd have to be in a boat. I am seldom found boating nowadays, and I've never been to San Francisco. (Did you know that Arizona has more boats per capita than any other state in the union? It's true!) I've been to the Stratosphere Casino in Las Vegas, but the only thing that fell on my head there was rain. Actually, the whole "being struck from above by a sack of potatoes dropped from considerable height" scenario isn't very likely, which makes it a terrible metaphor for inevitability. I guess I'm just not on top of my game today, which isn't surprising, considering my mood. This captivating femme fatale is known in Marvel Comic circles as Dark Phoenix. But, at the same time, she is also Jean Grey (a.k.a. Marvel Girl). Jean Grey is a telekinetic telepath (she has the ability to move objects with her mind and the ability to read the minds of others), and she's one of the original founding members of the X-Men. Jean Grey becomes Dark Phoenix when The Phoenix Force takes over her body and consciousness. Just what the heck is a Phoenix Force, you ask? From whence does it come, and what does it want? And why's it picking on Jean Grey? I'm not exactly sure. I looked on line for a cohesive explanation, and this was the best one I could find:

This captivating femme fatale is known in Marvel Comic circles as Dark Phoenix. But, at the same time, she is also Jean Grey (a.k.a. Marvel Girl). Jean Grey is a telekinetic telepath (she has the ability to move objects with her mind and the ability to read the minds of others), and she's one of the original founding members of the X-Men. Jean Grey becomes Dark Phoenix when The Phoenix Force takes over her body and consciousness. Just what the heck is a Phoenix Force, you ask? From whence does it come, and what does it want? And why's it picking on Jean Grey? I'm not exactly sure. I looked on line for a cohesive explanation, and this was the best one I could find: None of this means that I'll be moving into a basement and sealing all my reading material into little plastic bags. I reject the ideals of the comic enthusiast and their sweatpants-wearing, Taco Bell-centric lifestyle. I have no desire to see the She-Hulk and Wonder Woman wrestle in a tub filled with radioactive pudding. In fact, I feel only pity for the cripplingly large breasted comic book super heroines whose creators send them charging off into battle with nothing more than an enchanted corset and thigh high boots (and, for the very last time gentlemen, a cape is not a daytime accessory). I, personally, don't have an "ideal woman," but if I did, the ability to lift a tank wouldn't be a part of that ideal. I also reject the notion that I'm perpetuating a negative comic book enthusiast stereotype. Have you ever seen a Gay Pride March? I'd be happy to swap stereotypes anytime. I'm not passing judgment here anyway. I'm just saying that spending my weekends playing Dungeons and Dragons in the smoke-free back room of a comic book shop, slaying evil trolls with my magical elf, isn't my idea of a good time. If it were, I'd attend more Gay Pride Marches.

None of this means that I'll be moving into a basement and sealing all my reading material into little plastic bags. I reject the ideals of the comic enthusiast and their sweatpants-wearing, Taco Bell-centric lifestyle. I have no desire to see the She-Hulk and Wonder Woman wrestle in a tub filled with radioactive pudding. In fact, I feel only pity for the cripplingly large breasted comic book super heroines whose creators send them charging off into battle with nothing more than an enchanted corset and thigh high boots (and, for the very last time gentlemen, a cape is not a daytime accessory). I, personally, don't have an "ideal woman," but if I did, the ability to lift a tank wouldn't be a part of that ideal. I also reject the notion that I'm perpetuating a negative comic book enthusiast stereotype. Have you ever seen a Gay Pride March? I'd be happy to swap stereotypes anytime. I'm not passing judgment here anyway. I'm just saying that spending my weekends playing Dungeons and Dragons in the smoke-free back room of a comic book shop, slaying evil trolls with my magical elf, isn't my idea of a good time. If it were, I'd attend more Gay Pride Marches.  Anyway, "The Phoenix Saga" began in 1976 and has since become one of the most recurrent, rehashed, revised and convoluted story lines in comic book history. You'd be surprised how much trouble a bird-shaped nexus of psionic energy can be, and how difficult it's made life for Jean Grey. In a nutshell, when Jean Grey is left to her own devices, she's Miss Pretty and Perfect in classic comic book do-gooder sense. But when the Phoenix Force possesses her, she becomes Dark Phoenix and a heck of a lot more fun- kind of like Olivia Newton-John's transformation at the end of Grease, only darker. Dark Phoenix is arrogant and vengeful and says things like, "I am fire and life incarnate." She can destroy an entire planet and its billions of inhabitants with a thought. She has the power to unravel the very fabric of existence, and has come close to erasing the entire universe more than once.

Anyway, "The Phoenix Saga" began in 1976 and has since become one of the most recurrent, rehashed, revised and convoluted story lines in comic book history. You'd be surprised how much trouble a bird-shaped nexus of psionic energy can be, and how difficult it's made life for Jean Grey. In a nutshell, when Jean Grey is left to her own devices, she's Miss Pretty and Perfect in classic comic book do-gooder sense. But when the Phoenix Force possesses her, she becomes Dark Phoenix and a heck of a lot more fun- kind of like Olivia Newton-John's transformation at the end of Grease, only darker. Dark Phoenix is arrogant and vengeful and says things like, "I am fire and life incarnate." She can destroy an entire planet and its billions of inhabitants with a thought. She has the power to unravel the very fabric of existence, and has come close to erasing the entire universe more than once.  The green Phoenix is relatively easy to find. Dark Phoenix, however, is a "variant." This means that there fewer of them made. Where does one go to find a rare Dark Phoenix? eBay, of course.

The green Phoenix is relatively easy to find. Dark Phoenix, however, is a "variant." This means that there fewer of them made. Where does one go to find a rare Dark Phoenix? eBay, of course.